Before I built my first freight car, I had to design the trucks that support the car. Years ago, I had axles fabricated for me by a machine shop, based on dimension I scaled up from my previous "G" gauge railroad. I researched prototype trucks and settled on a basic arch bar truck. This uses a wooden bolster, holding frames made of 1/16" x 1/4" brass bars, with 3D printed journal boxes, and Delrin bearing sleeve inserts. The frames are held together with 2-56 brass threaded rods and nuts. This is a low speed railroad, so there are no springs in the side frames. My previous railroad, Big River Lines, used rigid frame trucks with no problems.

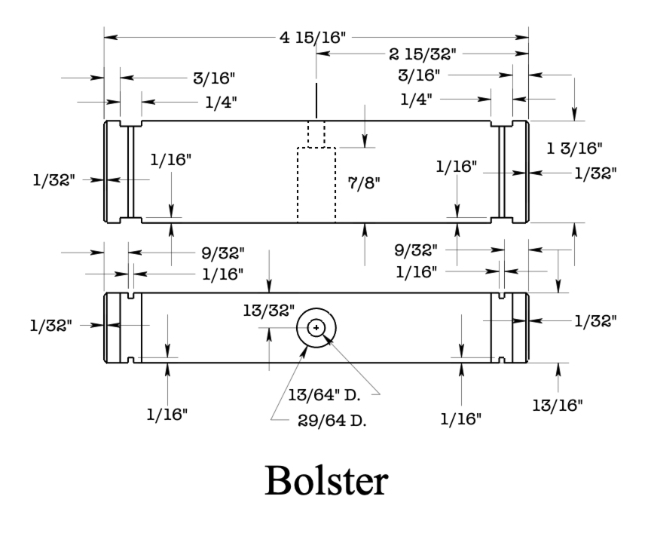

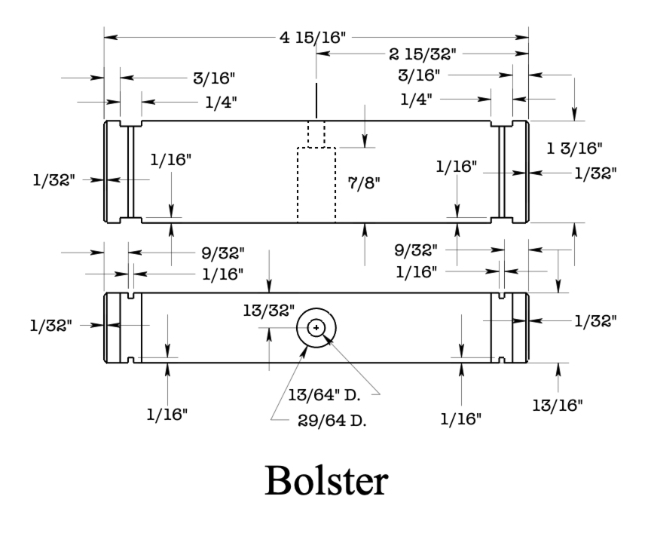

Here are the dimensions for the wooden bolster. The notches top and bottom, near each end, hold the frame bars, and the side notches hold threaded rods.

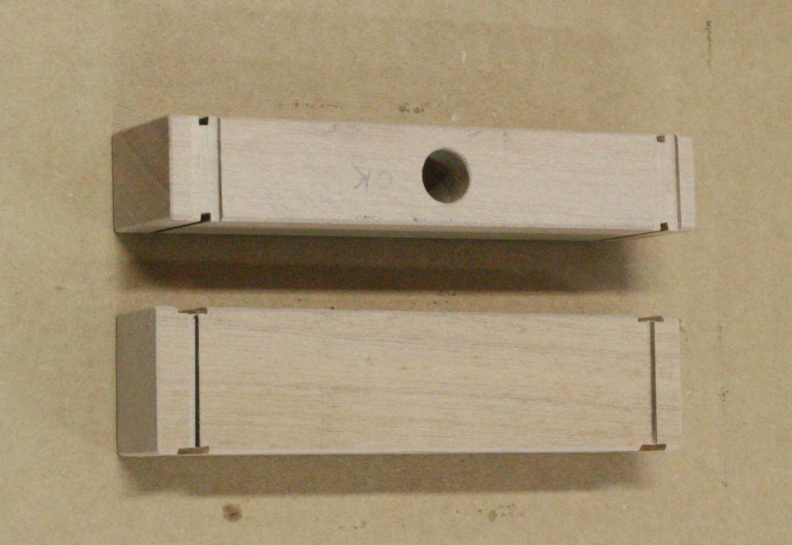

I use Madrone for fabricating the bolster. This shows the bottom and side views.

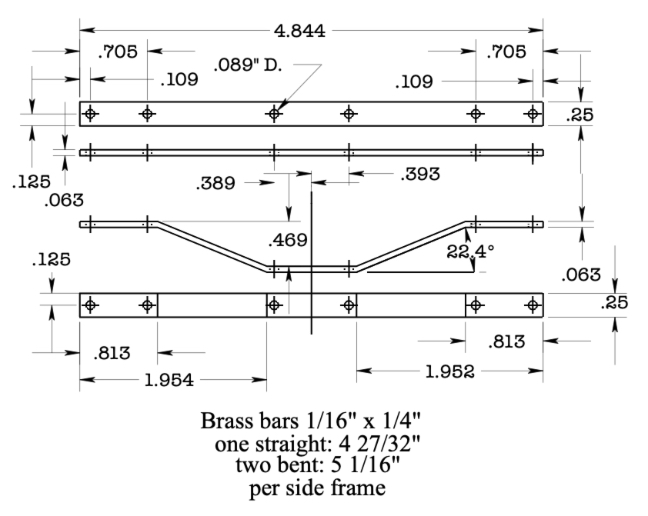

Two of the bent bars and one of the straight bars are needed for each side frame, with two frame sets for each truck. The holes are for the 6 pieces of 2-56 threaded rod. I use bar stock supplied by McMaster Carr. Here are the dimensions for the frame bars.

After the bars are cut to length, the bars to be bent are marked, and bent using a vise and a bending jig to get the angles right.

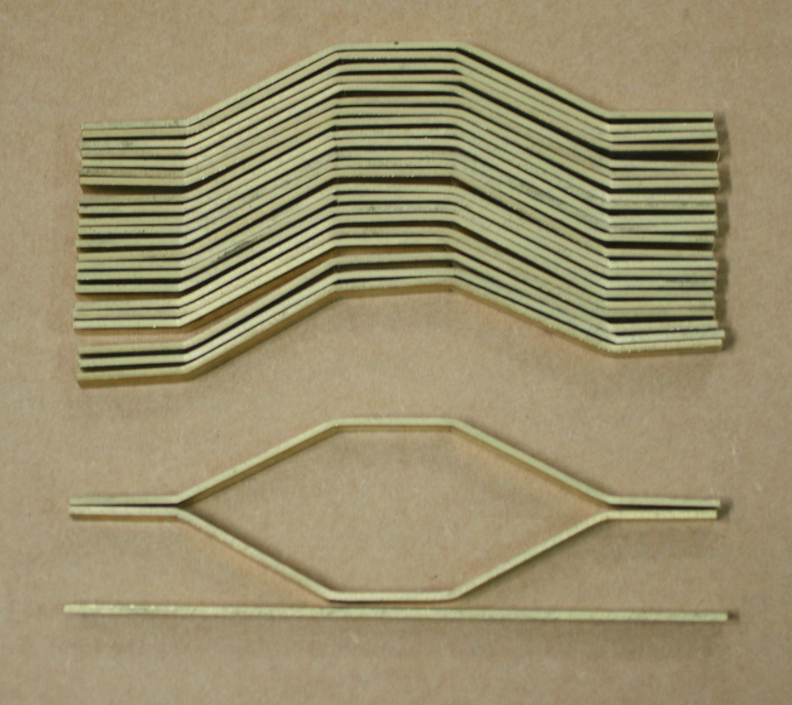

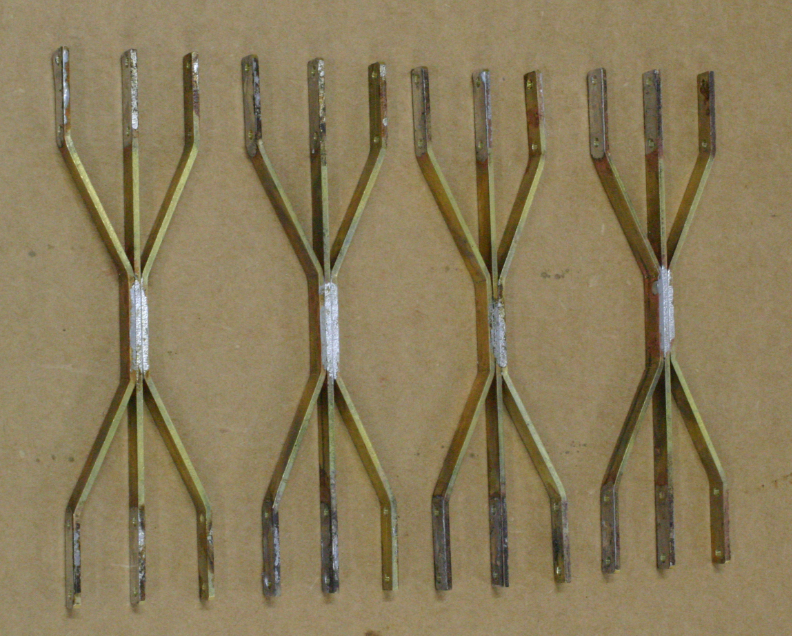

Here we see all the bent bars necessary for three pairs of trucks. At the bottom a pair of bent bars and a straight bar show the arrangement as they will be in the finished truck.

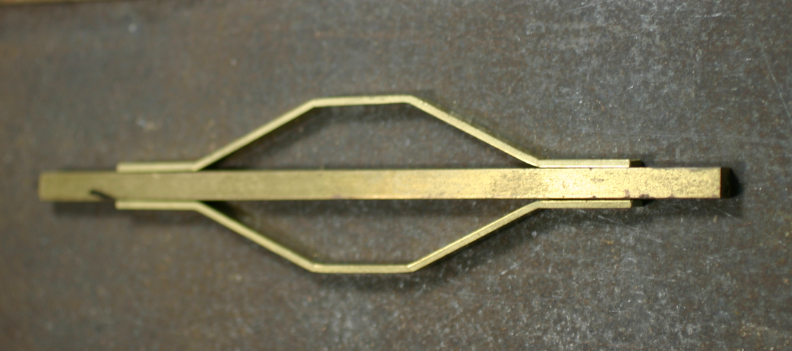

Each pair of bent bars are adjusted for final shape, using a piece of 1/4" x 1/4" brass bar. Each end must lay flush to the central bar, and must be the correct displacement from the central bar in the middle.

The threaded rod holes in each side frame set (2 bent bars and 1 straight bar) must be drilled in exactly the same location. This is done in two steps. Each set is held in a soldering jig, as shown below, and sweat soldered together. The jig is a ceramic plate, using small pins for location, with aluminum bar stock to orient the brass frame members, and a pair of wedges to clamp the pieces. The areas to be soldered have flux applied before being clamped into the jig. A torch is used to apply the heat.

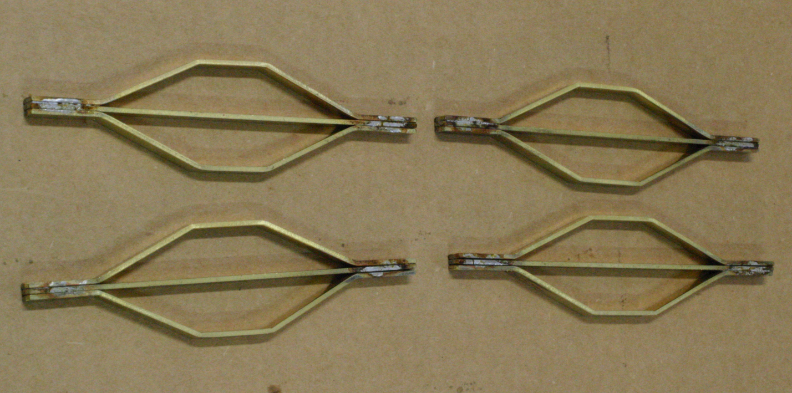

Here are several side frame sets ready to have two holes drilled at each end.

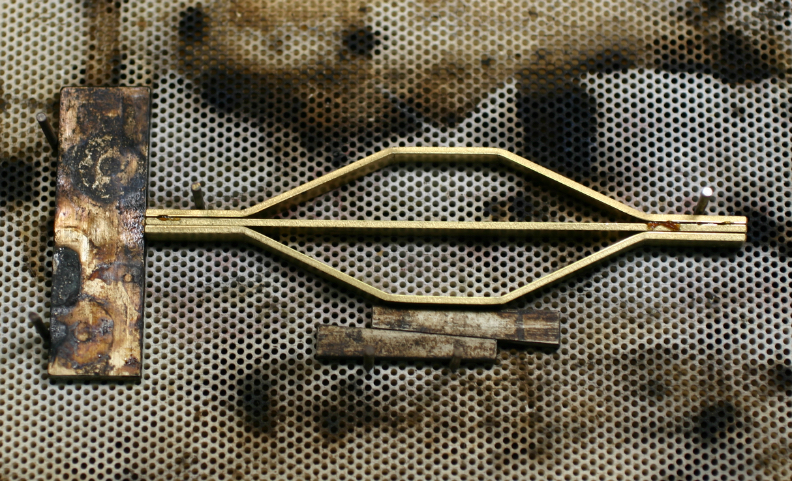

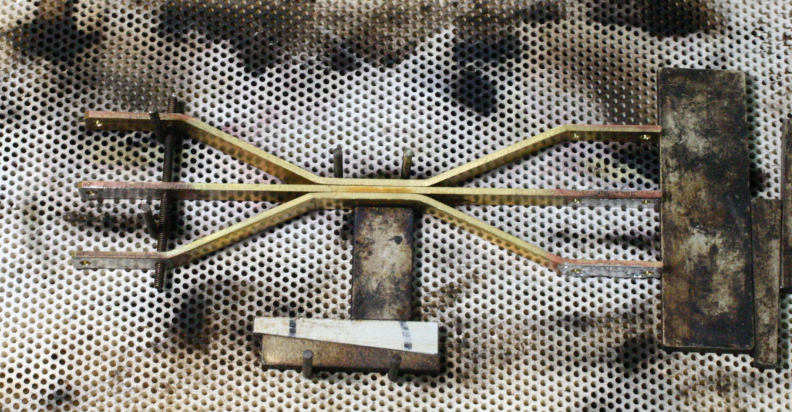

The three bars in a set are kept together for the rest of the fabrication process, and marked to preserve consistent orientation. After the first holes are drilled, the set is reheated, and the bars rearranged in a different jig orientation, to have the center pair of holes drilled. A piece of threaded rod (at the left) keeps the pieces in alignment, ready to be soldered. The end holes are visible.

Here are several sets ready for the center holes to be drilled.

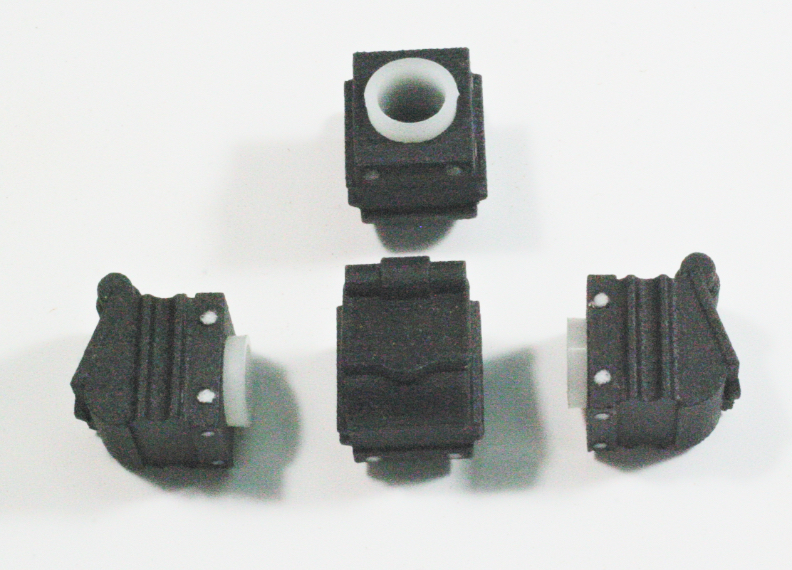

The nylon journal boxes are printed for me by Shapeways, with a black finish. Delrin inserts from McMaster Carr have been inserted.

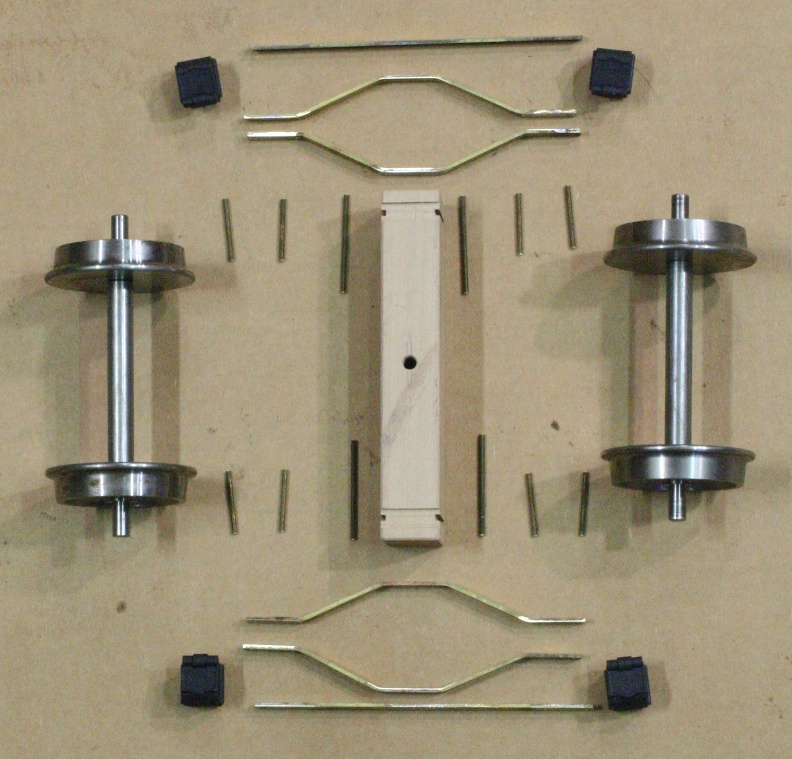

All the pieces for a single truck are shown laid out here. Twelve pieces of threaded rod from McMaster Carr have been cut to length.

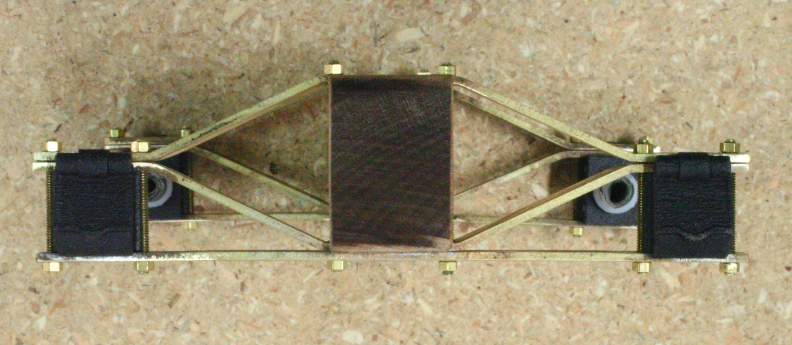

Here is an assembled frame, minus the axles, using 24 brass 2-56 nuts. Small rolls of newspaper have been inserted into the Delrin bearing to keep paint out. This is now ready for painting.

Before being spray painted with flat black primer, the ends of the axles are masked off to keep paint off the bearing surfaces for smooth rolling. The wheel treads are masked as well. All the axles are ready for painting.

The frames are mounted on sticks to be able to handle them well during the spray painting process. A simple jig supports the sticks. Here the frames are ready for painting.

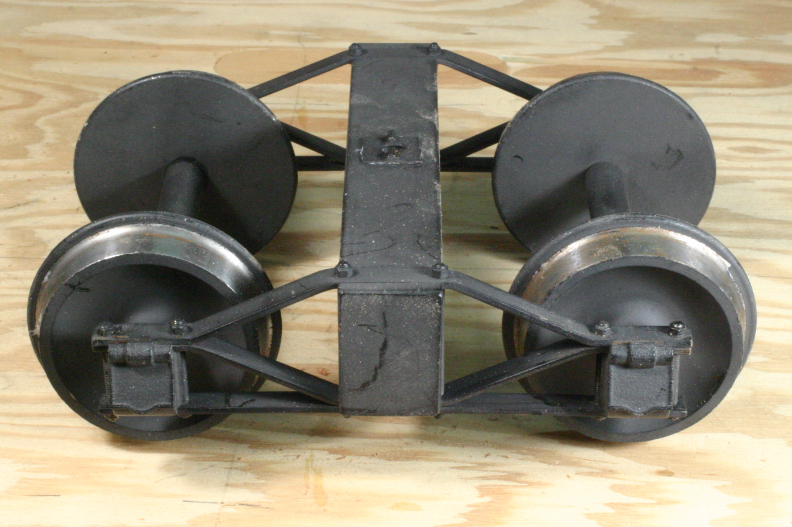

After painting, the masking tape is removed, and a pair of axles is installed into each frame. Here is the side view of a finished truck, ready to mounted on a freight car body.

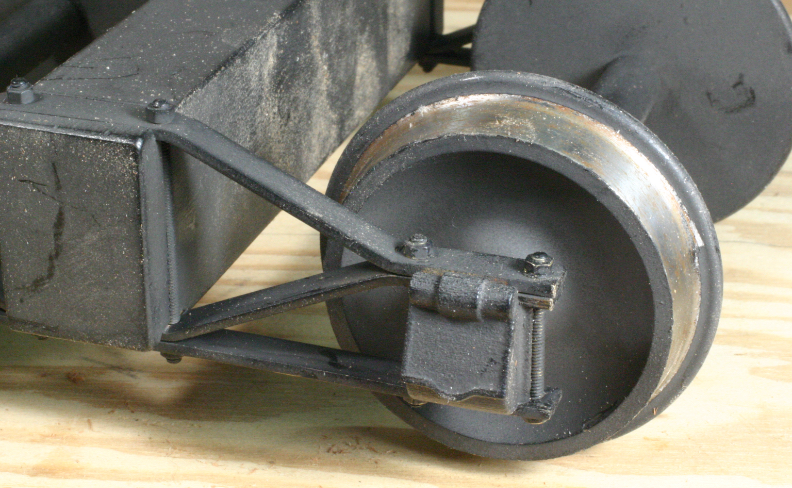

Here is a closer look.

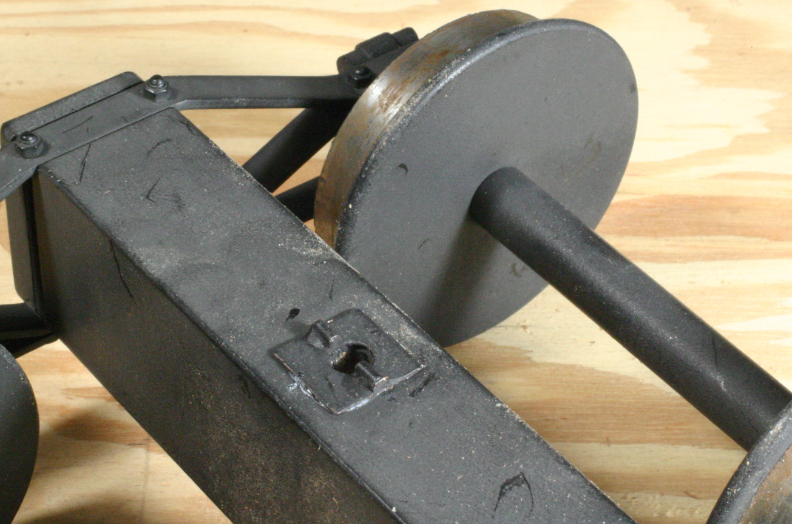

The trucks must be secured to the freight car body tightly enough to prevent wobble, but loose enough to pivot freely. In addition, the truck needs to be able to adjust to grade changes by tilting fore and aft somewhat. A fitting on the top of the bolster allows for that constrained movement, shown here in detail.